FCAW: Cored Wires Overview

Cored electrodes can provide a broad range of metallurgical and physical characteristics that may be difficult or impossible to achieve with traditional stick welding. The varied demands of maintenance welding make cored electrodes the ideal choice for many applications. Here is a look at some of the potential choices available to industry.

While traditional stick or shielded metal arc welding (SMAW) will always have its place, continued advances in cored electrodes make them an attractive solution to an ever-broadening range of welding requirements. Cored electrodes tend to provide higher deposition rates than those of other processes without developing excessive electrical resistance heating, even with relatively small diameter electrodes.

A cored electrode is a continuously fed tubular metal sheath with a core of powdered flux and/or alloying ingredients. These may include fluxing elements, deoxidizing and denitriding agents, and alloying materials, as well as elements that increase toughness and strength, improve corrosion resistance, and stabilize the arc. Typical core materials may include aluminum, calcium, carbon, chromium, iron, manganese, and other elements and materials. While flux-cored electrodes are more widely used, metal cored products are useful for adjusting the filler metal composition when welding alloy steels. The powders in metal cored electrodes generally aremetal and alloy powders, rather than compounds, producing only small islands of slag on the face of the weld. By contrast, flux-cored electrodes produce an extensive slag cover during welding, which supports and shapes the bead.

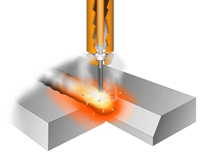

Flux-Cored Arc Welding

A flux contained within the tubular electrode produces the shielding and forms a slag for flux-cored arc welding (FCAW). Additional shielding may be provided by an externally supplied gas or gas mixture, in which case the process is referred to as gas-shielded (FCAW-GS). Otherwise, it is termed self-shielded (FCAW-SS). Electrode and flux composition are tailored to specific applications. Electrodes used with external gas shielding generally differ from those that are self-shielded. Within each category are several classes that together cover a broad range of welding applications.

Self-Shielded Flux-Cored Electrodes

Stick Welding With self-shielded FCAW, the heat of the arc causes decomposition and some vaporization of the electrode's flux core, which partially protects the molten metal (Figure 1). Because the flux ingredients introduce deoxidizing and denitriding agents, self-shielded FCAW is ideal for many types of field welding, especially under windy conditions. By contrast, the gas-shielded process may require the use of tents or other physical shields to protect the gas shielding from winds over about five mph. The self-shielded process also is more portable, since it requires only a wire feeder and constant-voltage power source. Gas tanks, regulators and hoses are unnecessary. This simplicity extends to the torch head, which allows the operator greater visibility of the work.

For high deposition welding applications, long electrode extensions (up to 3-3/4 in.) are used frequently. This preheats the electrode and decreases the welding current to produce ashallow penetrating welding bead, which is suitable for bridging gaps caused by poor fit-up on heavy, complex, or tubular pieces.

Various electrode types are designed for high-speed, single-pass welding, general purpose welding, structural fabrication, and high-strength pipe welding. Electrode diameters available range from as small as .030 in. to 5/32 in., depending upon the classification and application. Some are most suitable for use in flat and horizontal positions, while others can accommodate most or all positions. Typical applications vary from automatic welds on sheet metal to heavy steel structures in bridge construction, with almost everything in between.

Manufacturers have developed a broad range of electrodes to meet special conditions. Some can weld steel as thin as 20 gauge, while others can deposit 40 pounds of weld metal per hour. Within each classification, there may be several electrodes that meet the category's overall requirements, but each provides a different set of characteristics. Most manufacturers of consumables have ample test data and application information and should be consulted when selecting electrodes to meet specific conditions. Some manufacturers will actually design custom-filled FCAW electrodes for special applications.

Specific elements can be used to clean and desulphurize weld deposits by including them within the tubular electrodes, although they could not be incorporated as alloying elements during the processing of solid steel electrodes. This versatility with cored electrode composition and design results in welding consumables with excellent resistance to weld cracking on hard-to-weld steels such as high sulfur and high carbon grades.

Gas-Shielded Flux-Cored Electrodes

Gas-shielded FCAW (Figure 2) is similar to self-shielded but uses protective gas shielding in addition to the flux core. Shielding gases typically include CO2 or a mixture of argon and CO2, such as 75% Argon/25% CO2, 90% Argon/10% CO2, or others. The exact choice and blend of shielding gas will vary depending upon the electrode composition and desired arc characteristics.

With gas shielding, typically short electrode extensions (1/2" to 1-1/4") are used for most wire diameters. The use of larger electrode diameters (greater than 3/32") and the use of 100% CO2 shielding gas can result in welds having deep penetration. This is desirable for some welding applications to reduce required weld size or weld joint volume. Gas-shielded FCAW electrodes are most popular for automatic, semi-automatic and robotic welding of mild and low alloy steels. Representative applications include bridges, mining machinery, offshore drilling rigs, ships, structural and general fabrication.

Electrodes for gas-shielded FCAW are commonly available in mild steel and low alloy grades, in diameters that range from .035 in. to 1/8 in., depending upon the electrode type. Some are most suitable for downhand welding, while others can be used for out-of-position welding, and each produces a different set of physical, metallurgical and welding characteristics. A recent development is the emergence of low smoke or low fume flux-cored electrodes, particularly for use with gas shielding, to reduce welding fumes.

Electrode Development

Self-Shielded Flux-Cored Electrodes

Designed to provide their own shielding as well as various other functions, these electrodes have benefitted in several ways from metallurgical improvements. In about the mid -1960s , controlled amounts of aluminum were first used in these electrodes as an element to combine with nitrogen. It was found that adding other alloying elements, such as carbon and nickel, could improve ductility and increase notch toughness.

Such advances have led to the development of an entire series of self-shielded flux-cored electrodes. Lincoln Electric®, for example, offers more than 25 such electrodes in its product line. Some have been used in extremely demanding applications, such as offshore oil platforms, where Charpy V-notch and CTOD (cracked tip opening displacement) test requirements are stringent. Other developments include electrodes using new alloy types that will promote the welding of higher strength steel, electrodes with improved usability on galvanized steel, and specialty electrodes for the welding of cross-country pipe.

Gas-Shielded Flux-Cored Electrodes

Although not well-suited for outdoor use because wind can cause loss of shielding, these electrodes offer many advantages for other applications. The T-1 or rutile-bearing (containing titanium dioxide, a desirable slag ingredient) electrodes in this class are easy to use, have excellent spray transfer and may have lower fume generation. Out-of-position usability is high, with deposition rates of 6-1/2 to 7 pounds per hour easily achievable.

As with other cored electrodes, a wide range of choices provides great versatility. For example, rutile-bearing electrodes for both downhand and out-of-position welding are available in mild steel as well as a variety of alloy types. Another example is a family of patented extra-low hydrogen electrodes that incorporate hydrogen scavenger technology. These electrodes were developed to reduce the tendency for hydrogen cracking during the welding of high-strength steel.

Operator appeal is a constant goal. One area where gains are being made is in T-5 electrodes. While these fluoride-type electrodes provide greater crack resistance and meet certain Charpy V-notch requirements, they have always been more difficult to use, especially for out-of-position welds. Recent developments are targeted at creating T-5 electrodes that have the operator-friendly characteristics and positional versatility of the T-1 rutile-type electrodes.

Metal-Cored Electrodes

A metal-cored electrode is a composite electrode, generally consisting of a mild steel jacket with a core of specifically selected iron and other metal powders and alloys. Stabilizers and arc enhancers can be added easily, providing a wider operating window for the welder. Metal-cored electrodes are gas-shielded types that are an alternative to solid alloy electrodes. Versatility is possible with these electrodes because of the infinite alloy compositions that can be made easily by electrode manufacturers.

Special alloy combinations can be achieved that would be difficult or impractical with solid electrodes, including special types for welding higher strength steels. Versions that meet military and other specifications requiring low diffusible hydrogen are available. Metal-cored electrodes are being produced with 12% chromium for production welding of catalytic converters and other automotive exhaust components of 409 stainless steel. Another type incorporates chemistry that reduces surface tension of the weld puddle, for improved wetting action that produces a wider weld, useful in applications such as stitching parts together.

When a job calls for special electrodes, metal-cored electrodes are a more economical alternative to solid electrodes. Because the manufacturing process involves blending metal powders instead of creating a special melt of steel, small quantities are easier to produce, and minimum order quantities are much lower. As a result, metal-cored electrodes can be produced with shorter turnaround times and at lower cost than special-ordered solid electrodes.

Arc Enhancement and Wave Form Control

When metal-cored electrodes are combined with pulsed waveform control technology, several benefits occur. Using a metal-cored electrode in the pulse mode, as opposed to straight spray-type transfer, reduces the volume of smoke as well as the amount of spatter, particularly at low settings. Cored electrodes operate extremely well in a pulsed environment, especially with machines like Lincoln's Power Wave® 455M. These are inverter-based welding systems designed to combine ease of use and welding performance. They incorporate specific programs for pulsed welding of metal-cored electrodes as well as many other program selections. The Power Wave® 455M, in fact, can be reprogrammed by using software to create the ultimate arc for any application, at any time.

A typical application is the manufacture of automotive and truck mufflers from Type 409 stainless steel. These can be welded with an electrode consisting of a mild steel sheath and core materials that are blended to provide the proper amount of chromium and other elements for the stainless steel composition. Stick Welding When compared to the globular transfer normally used in this type of application, the use of pulsed wave form control will reduce heat and spatter. This leads to longer welding gun life and reduced maintenance because of less damage to fixturing, especially in high volume applications. With waveform control, pulsed operation provides better weld quality with the thinner materials (typically 16 gauge), high travel speeds and less than perfect fitup often encountered in this type of application.

Development Continues

Future development of cored electrodes will continue to provide solutions to welding problems as well as improving quality and increasing productivity. Another focus is the area of operator appeal, both through making electrodes easier to use and in reducing weld fumes through new, low-fume electrodes.

Higher strength is a goal for all processes, along with improved ductility and toughness. Special electrodes continue to be developed for high-strength steel applications such as in the offshore industry, but greater versatility and improved operator appeal are still a major focus of most development efforts.