There are a number of benefits for students and instructors regarding the use of VRTEX® Visual Cues. These benefits are supported by third party studies and user case studies. The objective of this Tips and Tricks document is to help the user understand how the Visual Cue for Travel Angle actually works.

The VRTEX® simulators all have the ability to recognize if a user starts a weld from the right or from the left side of a coupon (top or bottom). With VRTEX 360 Upgrade 6, when welding with either pipe and pipe on plate, the VRTEX will now also have the ability to recognize any changes in direction of travel.

Below are a few tips to illustrate what to look for when using the Travel Cue.

DIRECTION OF TRAVEL FOR FLAT, TEE, AND GROOVED PLATES:

When welding on the VRTEX 360 or the VRTEX Mobile, the user places the welding helmet on their head to become immersed in the virtual environment. Determining personal position (where to stand) is a big part of the training process. This is something the user will at some point need to figure out. The first step is to realize how to see the puddle and still establish the proper travel angle. The Visual Cue for Travel/Work Angle will be that guide.

A Green bubble in the crosshairs is the desired angle.

A good habit welding operators develop is the dry run pass. The idea is to simulate the entire motion of the weld without actually striking an arc. By performing a dry run, the welder can figure out how best to position themselves to be able to travel from the intend start to the finish of the weld as efficiently as possible.

The VRTEX® simulators recognize travel direction based on the starting point. For example, most right-handed welders would start a PUSH weld on the right side of the coupon and push the nozzle toward their body. To begin, position the welding device at the weld starting point so that the the Cue for Travel Angle is green and in the crosshairs.

EXERCISE 1:

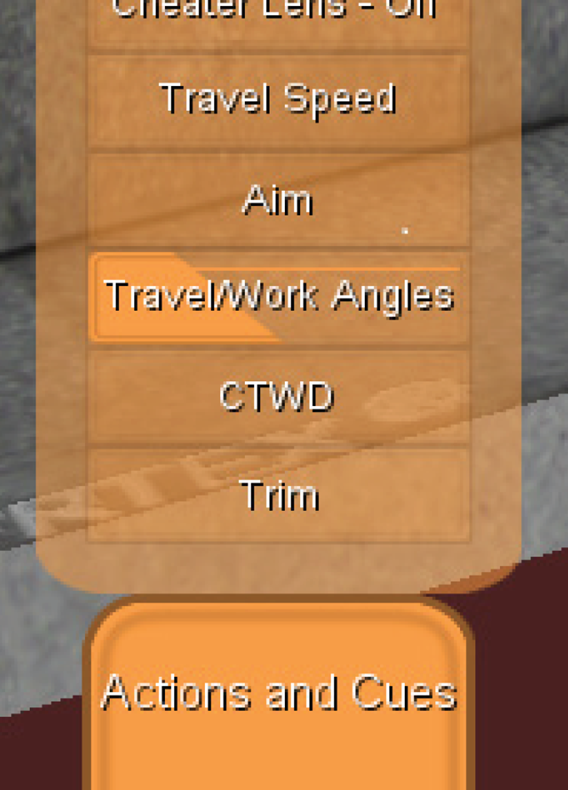

Set up a 2F GMAW weld. Prior to welding, press Actions and Cues. Select the cue for Travel/ Work Angles.

Right-handed trainees will start at the right side of the coupon. Prior to pressing the trigger, perform a dry run (simulate the motion of performing the entire weld), attempting to maintain angle cue crosshairs in the bubble, which will keep the color green. Green bubble for the angle cue.

NOTE: Halfway down the plate, the bubble will suddenly change from green to red (good to bad). The Angle Cue is not broken. The angle has not necessarily changed. This will happen because when the user reaches the halfway point the VRTEX® will assume the user is no longer starting from the right hand side. The VRTEX® now instead assumes the user is starting the weld from the left hand side.

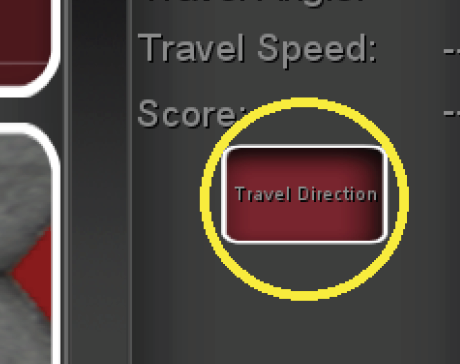

Change the monitor screen to the LASER screen (scoring screen). Note the Travel Direction arrow has not been triggered. The weld was not started. Therefore, Travel Direction has yet to be established. When performing the weld, Travel Direction will be established and the trainee will have the ability to keep the crosshairs in the bubble and maintain the green color throughout the weld.

EXERCISE 2:

Use the same weld and the same Angles cue. Prior to the dry run, place a small tack at the right end of the plate. This will now establish the Travel Direction as right to left.

Recreate the same dry run without pulling the trigger (weld motion without welding), and note that the Travel/Work Angle cue will now remain constant for the entire length of the coupon. The bubble will stay green even when the GMAW device is taken beyond the halfway point.

DIRECTION OF TRAVEL FOR PIPE ON PLATE UPGRADE:

The Pipe on Plate VRTEX 360 Upgrade 6 has changed the way the VRTEX® determines travel direction for traveling in a circle. The scoring and Travel Cue for travel direction will now be determined as soon as the machine detects the choice of travel progression. Regardless of how many starts and stops a user might make, the travel direction can now constantly be reestablished.

EXERCISE 3:

Set up for 2F Pipe on Plate using the GMAW Short Arc process.

Press the Actions and Cues icon. Press Travel/ Work Angles. Under the helmet, position for a PUSH progression with the GMAW device coming towards the body. Place the nozzle into the starting position. Angle the device so that the Angle Cue is green and in the crosshairs.

Begin welding in the proper direction and attempt to maintain the green cue. Stop welding.DO NOT PRESS END PASS.

NOTE: Prior to striking an arc the VRTEX® assumes direction of travel based on positioning. It assumes you are standing in the correct spot for the chosen technique. When welding begins and the unit determines the direction of the weld, the machine will automatically adjust.

EXERCISE 4:

Using the same weld referenced above that has already been started, position to complete a different section of the coupon. Place the nozzle in the starting position and angle the GMAW device so that the Angles cue is green and in the crosshair.

This time do not use the PUSH progression coming towards the body , but instead start welding using the DRAG technique moving away from the body.

Notice that the Work and Travel Angle cue will now suddenly change from green to red (outside the crosshairs).

The VRTEX recognizes the new travel direction.

Scoring and cues will continue to recognize the weld is a PUSH and will thus determine the needed angle adjustment.

Continued changes in travel direction will automatically require Travel Angle adjustments.

MODIFY THE VRTEX® WPS TO MATCH YOUR PROGRAM:

Remember, the VRTEX® simulators each allow for changes in travel progression – changing PUSH to DRAG, up to down. The VRTEX® scoring and visual cues will recognize these changes.

See the Tips and Tricks “Change from PUSH to DRAG” for details.